Our laboratory

Welcome to our laboratory

In this area we explain some of our testing machines and their functionalities, so that you can get an idea about our quality assurance and testing. Cick here to go back to the quality area.

Tension/compression testing machine

With this machine we can test different components of the shoes for their tension and compression resistance as well as for their damping properties. The shoe is clamped in the machine and a pressure/compression is exerted on the part to be controlled. The power is slowly increased and it is measured, for example, what is the maximum power for the adhesive joints. Joint surfaces of soles, heel counters and toe caps can be systematically reviewed in this way and, if it is necessary, improved.

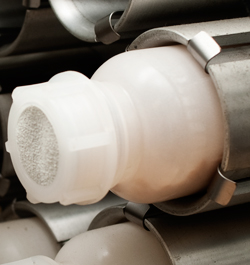

Penetrometer

This tester measures the water tightness of the used materials . A sample of the material is clamped into the machine, immersed in water, and moved until the water penetrates the sample. The meter is stopped by the electric voltage which emerges during penetration. The compression can be specified as a percentage and simulates the material compression, which occurs in a walking motion in the real world (dynamic method). In this way it is possible to measure how long the materials can actually withstand the water.

Sand-bath

With this machine, we measure the resistance of the sole and its insulation properties on extremely hot soils. The sand is heated depending on the procedure up to 250°C / 482°F, the shoe is then put into the bath so that the sole protrudes only one centimeter. After 10, 20, 30 or 40 minutes the internal temperature increase inside the shoe is measured. At the end of the test the damage and handling marks are tested too. According to the European standard for fire boots (EN 15090) the boots are tested in a sand bath heated to 250°C / 482°F and at a room temperature of 22°C / 72°F: withing 10 minutes the temperature increase must not exceed 20°C / 36°F (= 42°C / 108°F). The temperature of our boots only increases by 1,2°C / 2,1°F, an almost negligible difference! And after 40 minutes the VÃLKL sole naturally has no damage at all.

Flexometer

The Flexometer checks the the surface leather uppers. In this case a leather sample is clamped into the flexometer and folded over an over. The number of folds can be set individually. Generated by the movement of the upper leather is extremely stressed. After several hours it is possible to see whether the leather shows cracks.

Water-vapour-permeability testing machine

The water vapor content in the shoe is largely responsible for the foot climate. With this machine, we can determine how well the used material allows the passing of the water vapor to the outside. The test equipment used is hygroscopic (moisture attracting). The probe used is dried, weighed, placed in a dry container and sealed with the together with the tested material. Thereafter, the container is moved in an air conditioned room. After a given time, the weight increase of the test device is detected. Thus, one can determine exactly how much water vapor is passed through the material under testing.